Grbl Laser Engraver Software

This procedure is specific for Ortur products.

Fixes:

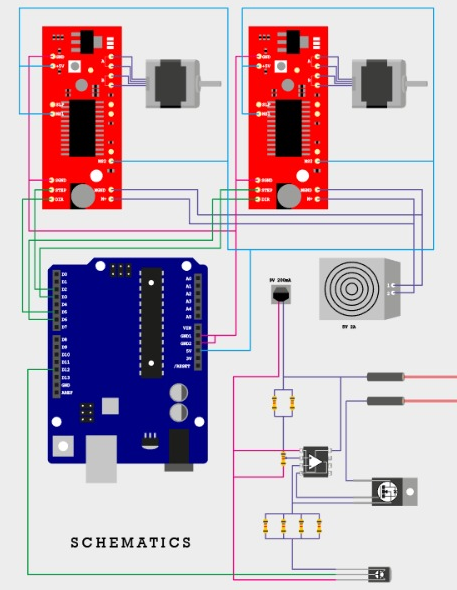

.The PiBot Version Grbl Modificatione From the original version GRBL.fully Reserve the Original Version of the Function and Tested on the Real CNC Machine and Laser Engraver. The following Opensource Software we have tested. Also your can used others Grbl Software and sender as your like, In theory, they can work!. CNC 3018 (Pro) Software: 6 Best Programs. Published Aug 13, 2020. CNC 3018 software comes in many forms. Unlock the potential of your machine with these six powerful tools. LaserGRBL is open source laser engraving software which is free to download and use. This free software has many useful functions, but one feature I want to highlight right away is its ability to create G Code. Unlike Candle and UGS software for a GRBL milling machine, LaserGRBL is the only software you will need to start using your cnc Laser.

EzGraver is a free open source laser engraving software for Windows. Through this software, you can instruct various types of laser engraving machines to engrave a predefined design over a selected material. To import predefined designs, you can import images of various formats like BMP, GIF, ICO, JPG, PNG, TIFF, and more. Most of the 3018 style Cnc engravers come equipped with Arduino clone hardware so they will be delivered with copies of Candle or other Grbl based software to control these machines. I use Candle for my 3018 pro machine and I have a full review of this machine at this link, 3018 review.

- Pause/Resume issue been corrected. Laser Pause/Resume functions now work as expected (is now possible to use LaserGRBL auto-cooling)

- Corrected False positive [Check Limits] on Pro Motherboards (RJ connector/Vertical buttons boards);

Improvements

- GRBL Core Upgrade from 1.1f to 1.1h;

- Optimization of USB Driver Library. Attempt to address disconect issues/Alarm 3;

- Fan Delay ShutDown Function. Fan will Remain on from 30 to 120 seconds, based upon the length of time and maximum power of the just finished engraving.

- G-Shock Sensor Algorithm. New algorithm reduces the amount of false positives;

You can find all information about firmware upgrade in ortur firmware website.

BE CARE TO FOLLOW EXACTLY ALL THE INSTRUCTION

A WRONG FIRMWARE INSTALLATION CAN BROKE THE CONTROLLER

Download files

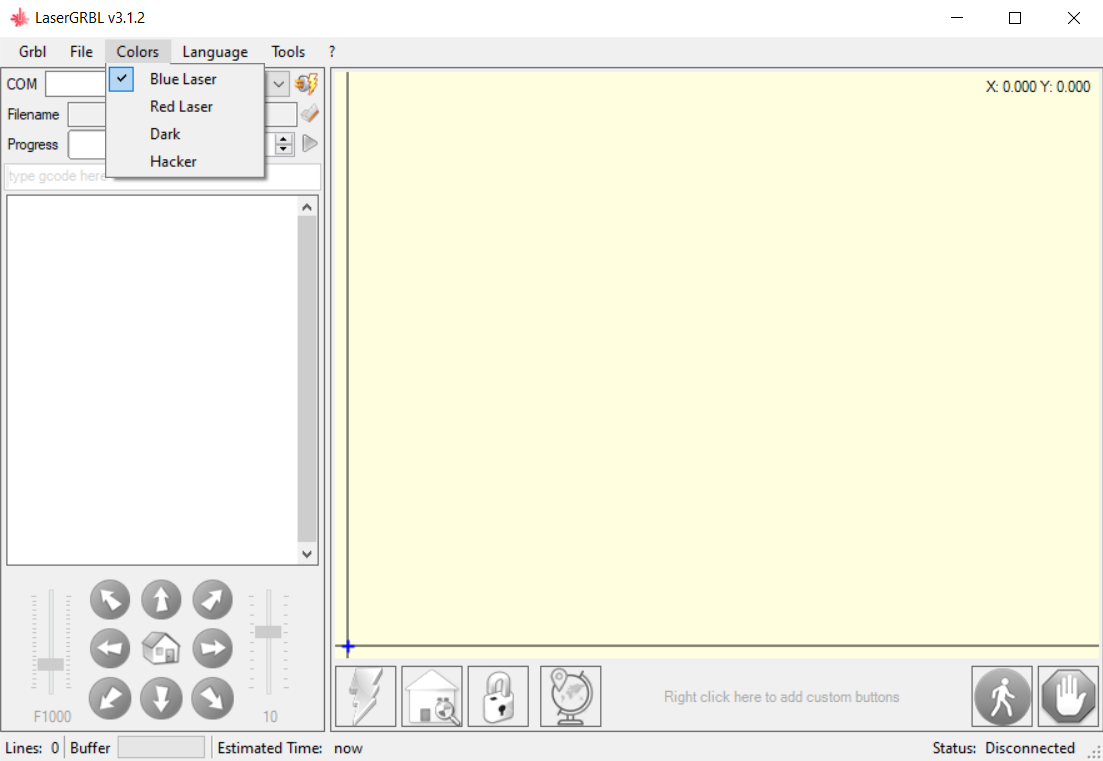

LaserGRBL is an excellent and practical open source control software in the field of laser engraving. Compared with similar software, it has a simple interface, simple operation, and supports multiple languages. There are a lot of learning resources used on the Internet, which is convenient for beginners to understand and master the software. Mastering a laser engraving software is the basic condition for using a laser engraving machine. It is recommended that beginners first learn the operation method of the software online before using it to prevent damage to the laser engraving machine and surrounding items by improper operation

Download from Laser GRBL official website or ask our customer service to get The archive contains two files:

1.CH340 USB driver Unzip the package and find the file

Grbl Software For Laser Engraver

Double-click to install, the user needs to install this driver when running the software for the first time. 2.Laser GRBL software Locate the file in the archive (install.exe) and double-click it to install it.

Basic operation

Operation notice

1.Install the machine according to the installation instructions, connect the line. 2.Download Laser GRBL software and install.

3.Power on the motherboard with the power adapter.

4.After the power is turned on, it can be operated online through the computer or offline through the touch screen on the machine (the online operation and offline operation are described in detail later).

5.Place the material to be engraved in the working area of the engraving machine.

6.Turn on the low light, focus by rotating the laser focus knob until a very bright spot appears, then the focus is complete.

7.Move to the position you want to engrave and click “Positioning”. This point is the machine zero.

8.Select the file to be engraved, select the engraving mode, and then click “Border”. At this time, the weak light is turned on, and you can walk along the largest frame of the engraved picture or text, so that you can know that the engraved file is probably engraved in where. If the location is not suitable, you can relocation it until you are sure.

9.Once the positioning is complete, click on “Engraving”

10.During the engraving process, the point “pause”, the machine stops moving, the laser turns off; the point “stops”, the laser turns off, the machine returns to zero.

11.After the engraving is completed, the laser is turned off and the machine returns to zero.

Online operation

Online operation is the operation of controlling the device through software after the device is connected to the computer.

1.Install the software an USB driver

2.Connect the device to the computer with a USB cable

3.Open the Laser GRBL software, select the COM port (except COM1, you can plug and unplug the USB cable to see which one is) and the baud rate (generally set to 115200), then click the connection, the color of the button will become darker after the connection is successful (if Click the connect button and the color does not become darker. You can unplug the USB cable and plug it in again.)

4.After the connection is successful, click “File” on the menu bar of the interface to enter the selection file interface, select “Open File”, import the picture to be carved, etc.

5.Select the file to be engraved, click “Open”, the “Input Raster Image” dialog box will pop up. Here is the setting engraving mode and some other engraving parameters. Click “Next” after setting.

6.Click “Next” to pop up the “Target Image” dialog box, where you can set the engraving speed, minimum power and maximum power and the length and width of the image to be engraved and offset. Click “Create” after setting.

7.After clicking “Create”, enter the preparation for engraving.

Move to the position you want to engrave, click the “Position” button (the position where the laser head is located at the lower left corner of the engraved pattern), set the number of times to be engraved, and click the “Start Engraving” button to start the engraving. After the engraving is completed, the machine returns to the zero position.